Vertical Roller Mill

- Type:Grinding Mill

- Model:Vertical Roller Mill

- Trademark:SBM

- Certificate:ISO9001: 2000

- Origin:China

- Capacity:5-18TPH

Two Types of vertical roller mill

New type vertical roller mill is SBM to solve the industrial grinding mill low yield , energy consumption higher technical difficulties, absorbing advanced technologies from Europe and combination of SBM grinding milling machine many years design advanced manufacturing concept and the needs of the market, after years of painstaking the improved design of large grinding equipment.

We have two types of vertical roller mill: LM vertical grinding mill and LUM ultrafine vertical roller mill, they adopted the structure design is reasonable and reliable, with advanced technological process, drying, grinding, powder selection, promotion in one, especially in the large grinding process, fully meet the needs of customers, the main technical, economic indicators have reached the international advanced level. Widely used in cement, electric power, metallurgy, chemical industry, non-metallic mineral industries, large milling processing is especially suitable for various ores, the massive, granular and powdery materials into the required powder material.

vertical roller mill operation

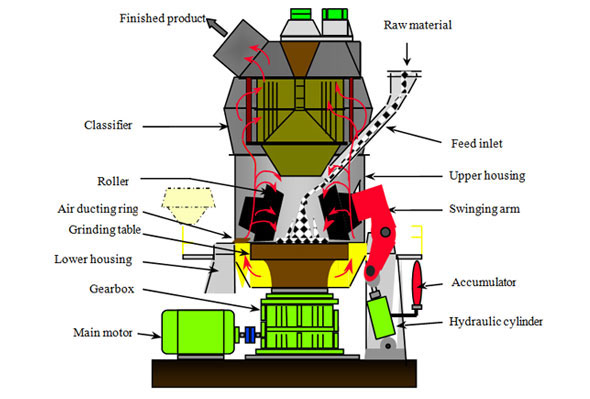

The main structure of the vertical roller mill is consist of separator,the grinding disc device, grinding roll device, a pressure device, reducer, motor, shell and other components.

- 1.The separator is an important component of the product thickness decide mill, comprising a driving device, a speed adjustable guide vanes, rotor, casing, coarse powder blanking cone outlet, etc., is a kind of powder selecting device, energy saving, fast and efficient.

- 2.The grinding roller is the main component of rolling grinding of materials. It was packed in a bent arm grinding machine, under the action of external force, pressed in the disc materials, driven by a millstone, rotate the grinding roller, so that the material is compacted and crushing.

- 3.Grinding disc is fixed on the output shaft of the reducer, the upper millstone for bed, with an annular groove material bed, the material is in an annular groove is roll grinding crushed.

- 4.The pressure device is to provide the milling pressure grinding roller parts, which is composed of high pressure oil station, hydraulic cylinder rod, an energy accumulator and the like, can exert enough pressure to make the material crushing and grinding roller.

- 5.The speed reducer is the main power transmission components, high yield powder preparation grinding disc speed reducer output shaft speed is of all kinds of material over a hundred kinds of his industry.

The structure of vertical roller mill is simple, compact and small construction area which is equipped with automatic control system, which enables remote control, easy to operate; through overhaul cylinder, turn rotating arm, can easily and quickly replace the roller sleeve, liner, reduce business downtime . Vertical mill itself splitter, no additional separator and lifting equipment. The mill dusty gas can be collected directly from the bag filter or electrostatic precipitator. In addition, the vertical mill fully enclosed system, the system is under negative pressure, no dust, clean environment.

Get Price And Support

Simply complete the form below, click submit, you will get the price list and a SBM representative will contact you within one business day. Please also feel free to contact us by email or phone. ( * Denotes a required field).